Transitioning to E-Invoice Effortlessly Now Transitioning to E-Invoice Effortlessly Now Transitioning to E-Invoice Effortlessly Now

Case Study

A prominent manufacturing company in Malaysia, operating multiple branches, faced challenges in streamlining their operations. They relied heavily on manual invoicing through Excel spreadsheets, resulting in inefficiencies, errors, and communication gaps between departments. The company’s growth and increasing complexity of operations highlighted the need for a centralized, digital solution to manage invoicing, inventory, and production across all branches.

As this manufacturing company expanded, it became increasingly clear that their existing processes could not keep up with operational demands. They were heavily reliant on manual systems, which were difficult to manage and prone to errors. High staff turnover became a frequent issue, partly due to the training-intensive and cumbersome nature of these outdated systems. Departments operated independently with little to no communication between them, creating an environment where important updates—such as inventory levels, production timelines, or customer orders—were not effectively shared. This lack of connectivity led to frequent delays, miscommunications, and inconsistent customer service, as each department worked in its own silo without a clear view of the overall operations.

These issues were compounded by multi-branch management challenges. With limited access to real-time data, senior management was unable to track inventory and sales across branches accurately. Decisions were often made based on incomplete or outdated information, creating missed opportunities and leading to less-than-optimal outcomes. Moreover, the company’s internal system could only be accessed on-premises, meaning that any critical data or updates were out of reach once office hours ended. This restriction further limited management’s ability to respond promptly to issues or make informed decisions outside regular working hours.

To make matters worse, the company had no way of tracking real-time production status, leaving the management team in the dark about the actual progress on the factory floor. Without a clear, up-to-date overview of ongoing production, they struggled to monitor and adjust schedules to meet changing demands or address urgent needs.

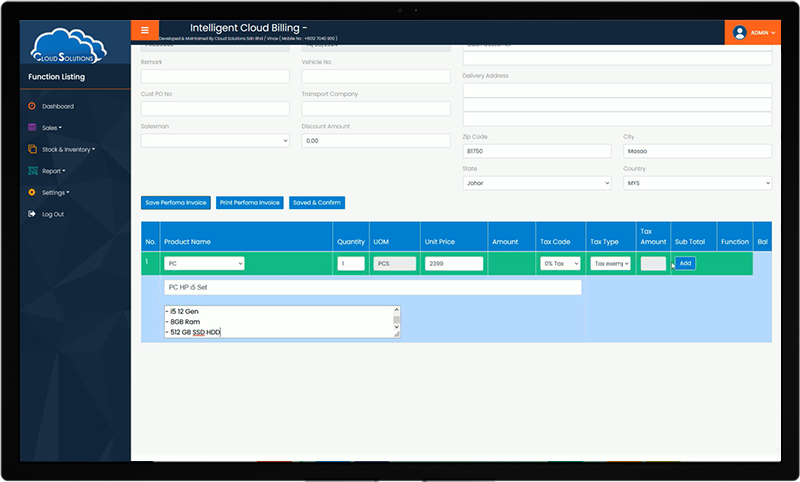

Cloud Solutions implemented a tailored, cloud-based e-invoicing and operations management system to address the client’s challenges. This solution offered:

With the cloud system, management could view real-time sales, inventory, and production data from any device, at any time. This provided the visibility needed to make timely, informed decisions and eliminated the need for branches to submit daily reports to HQ.

The cloud-based platform centralized data across all branches, allowing management to track stock levels, sales, and customer interactions in real time. This improved operational efficiency and provided a unified view of all branches.

The solution facilitated data sharing across departments. For example, production managers could view purchase orders placed by the procurement team, enabling faster response to urgent production needs. This transparency reduced delays and allowed departments to work more collaboratively.

The system included an automatic purchase order generation feature, triggered by pre-set minimum stock levels. This automation ensured that inventory remained at optimal levels, reducing stockouts and interruptions in production.

To enhance accessibility, Cloud Solutions created self-service portals for both sales teams and customers. Sales representatives could log in to check customer invoices and outstanding balances on the go, while customers could access their sales invoices and order statuses. This streamlined customer communication and reduced the need for back-and-forth inquiries.

The implementation of Cloud Solutions’ cloud-based system led to significant improvements in the client’s operations:

By automating manual processes and enabling real-time access to data, the company reduced its dependency on staff-intensive tasks. The system cut down on operational costs and supported higher productivity, even with existing staffing levels

With live access to inventory and production data across branches, management could make faster, more accurate decisions that were responsive to actual demand and conditions.

The centralized platform enabled efficient multi-branch management, allowing the business to scale without losing control over inventory, sales, or customer service.

The dedicated portals empowered sales teams and customers with the information they needed, reducing wait times and improving overall satisfaction. The transparency and accessibility of data also fostered a more collaborative, satisfied workforce.

By partnering with Cloud Solutions, this manufacturing company transformed its operations from disconnected and error-prone to efficient, connected, and responsive. The cloud-based system has not only reduced costs and improved productivity but has also positioned the company to scale operations confidently with real-time data and automated processes.

Learn how Cloud Solutions can help streamline your operations and drive productivity with a tailored, cloud-based solution.